Digital, Paperless Asset Assignment

Digital asset management is the process of organizing, tracking, and controlling company assets—both physical equipment and digital files. It creates clear accountability with a record of who has each item, when it was issued, and when it’s due back. This helps maintain order, reduce loss, and prevent theft.

- The employee confirms receipt digitally and can see in their personal portal what has been issued to them.

- Aptien automatically alerts you about equipment expiration so you can plan replacements in advance

- The asset manager can see where and who currently has each item.

- Aptien keeps a clear record of who has what, when it was issued, and when it should be returned

Who is Involved in the Asset Assignment?

The digital asset assignment process involves two main roles:

- Asset/Equipment Manager: (Responsible Person) Typically a manager or administrator who checks out equipment and ensures proper assignment and tracking.

- Employee: The employee receives the equipment and confirms receipt on-screen, taking responsibility for it until it’s returned. The employee does not need to be logged into the system at checkout; they simply confirm by signing on the screen.

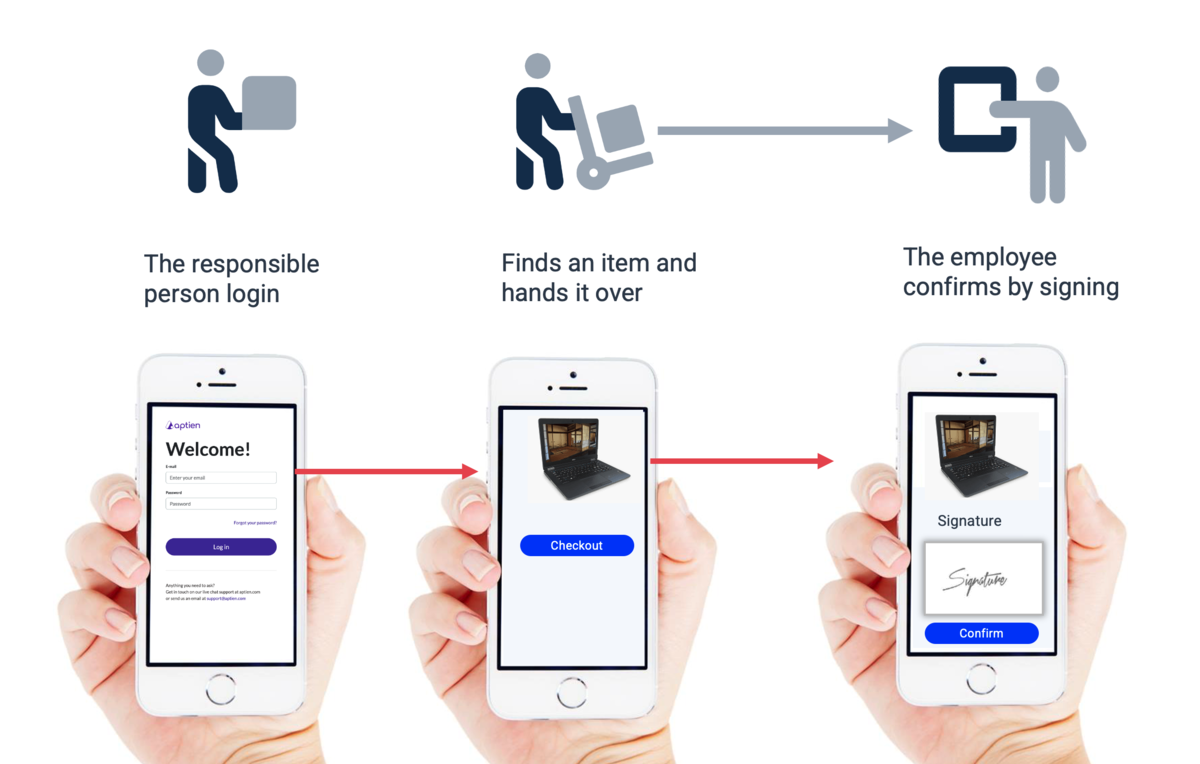

How Digital Checkout Process Works

The digital asset management process is straightforward and easy to do:

- Manager as a a responsible person (e.g., manager or supervisor) logs in

- Manager initiates the checkout process in Aptien by selecting the items to be assigned.

- Assignment: The employee confirms receipt of the equipment via a digital signature or button.

- Tracking: The equipment is tracked in the employee's profile, allowing easy monitoring of assigned equipment

Assigning or Issuing Equipment

Using digital digital asset management, you can efficiently manage the transfer of equipment such as devices, machines, or protective gear, which is common in business operations.

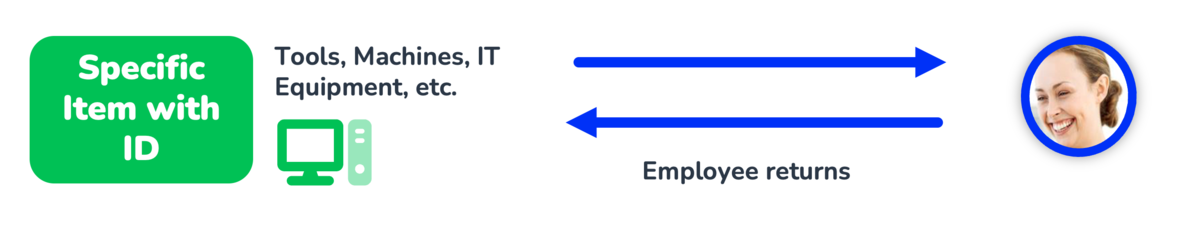

1. Specific Items (e.g., Machines, Devices, Computers)

- When handing over a specific item (like a laptop, phone, car, SIM card, or parking card), record it with a unique identifier (inventory number, ID, serial number, registration mark, QR code, card number, etc.).

- Each item is assigned to one person.

- The item is usually returned after a project or contract ends, the warranty expires, or the employee leaves the company.

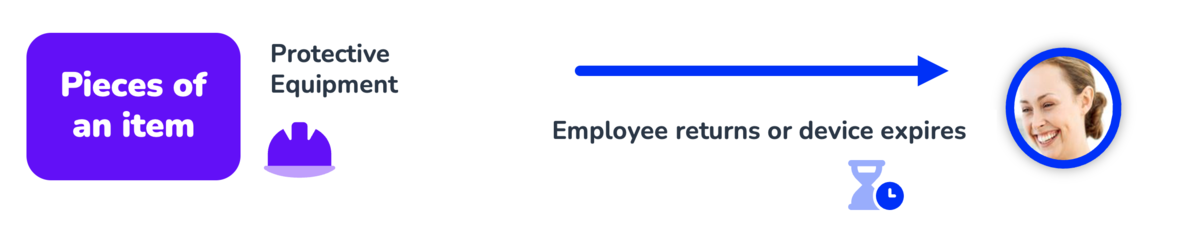

2. Multiple Pieces of Work Equipment or Supplies

- When issuing multiple pieces of work equipment, you don't track each item individually (often impractical).

- Instead, track what and how much each worker receives.

- This includes protective gear like uniforms, shoes, safety glasses, overalls, helmets, and shirts.

- Monitor the expiration or lifespan of these items to manage replacements.

- Equipment is issued in various sizes (e.g., shoe size, helmet size), and you can track these sizes for each worker.

- Use this information to plan and document future purchases based on size requirements.

Who Can Check out Equipment and to Whom

- Manager (responsible person) - a designated staff member authorized to issue or receive equipment and who sees the Check Out/Check In button. Must be signed in to the system.

- Recipient: typically an employee who must have a user account. They acknowledge that the item was issued to them. They do not need to be signed in; they simply confirm on-screen with a signature.

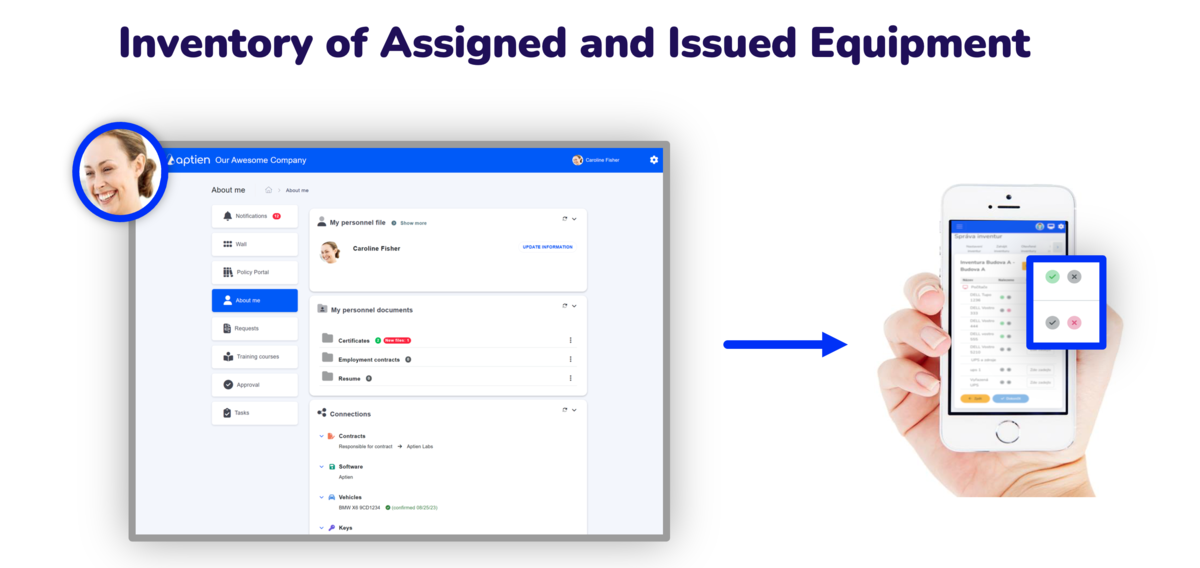

Verification Using Personal Inventory Audit

- Each employee can see all entrusted or transferred equipment on their personal page.

- You can check everything at any time, verify the actual state of things and run an inventory of entrusted property.

Summary of Key Features of Digital Equipment Checkout

- Check out specific assets with unique IDs (e.g., a laptop with an asset tag) or bulk items tracked by quantity

- Managers with the right permissions can start checkouts and returns using the action button in the register

- Employees confirm chekout with an on-screen signature or another approved method

- On the employee profile you always have an online overview of issued items

- Always know what’s in circulation and use better data to plan purchasing

- Employees can see on their profile which assets are issued or assigned to them

Use Cases for SMBs

Digital equipment checkout is flexible and works across many industries:

- Construction & Manufacturing: Tools, PPE (hard hats, vests), and tablets can be assigned at the start of a shift and tracked for return at the end of the day.

- Office: Laptops, projectors, pool vehicles, and access badges can be managed efficiently, reducing admin workload.

Benefits for Small and Mid-sized Businesses

- Electronic checkout eliminates paperwork and gives instant visibility into who has what

- Cost savings: Tracking equipment reduces loss and theft, saving your company money

- Greater accountability: Employees are more likely to care for company property when they know it’s assigned to them

- Simplified operations: The checkout and return process becomes more efficient, reducing administrative overhead

- Compliance support: In regulated or safety-critical industries, asset management helps ensure employees have required equipment and supports compliance