Reactive maintenance addresses failures and repairs

Corrective, reactive maintenance is simply handling breakdowns and failures. Reactive maintenance responds to a failure after it occurs — unlike preventive maintenance, which aims to prevent failures.

Examples of corrective maintenance tasks

- repairing equipment after a user reports a problem

- fixing faults found by monitoring systems

- repairing defects found during routine inspections

- resolving incidents that interrupt operations

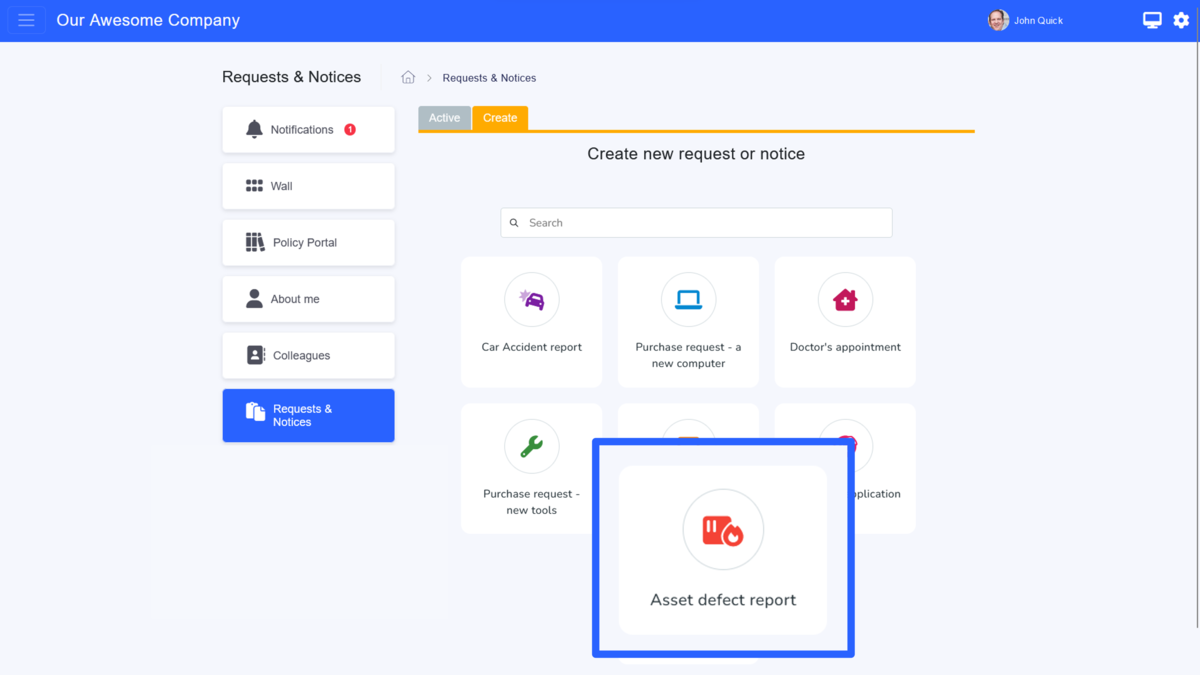

How to Report Faults, Defects and Failures

- Most reactive maintenance starts when someone reports a problem or equipment failure.

- Make sure you have a simple, reliable reporting system so staff can report a fault. Reports should enter a clear workflow so a responsible person or technician picks them up and fixes the issue promptly.

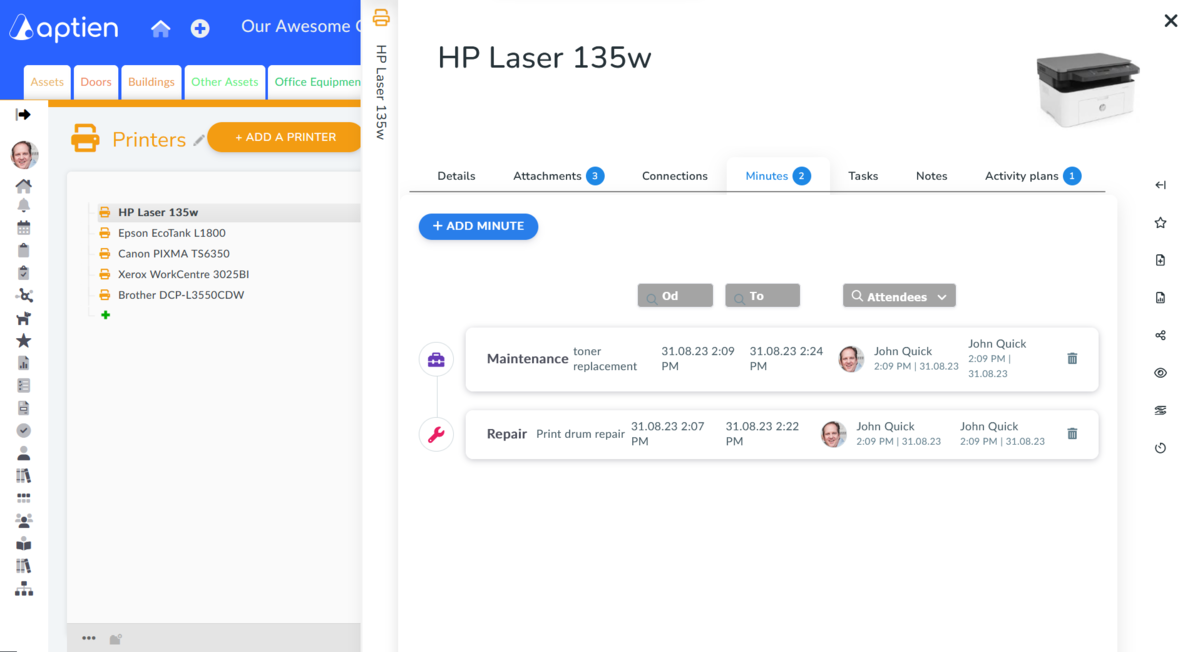

How to Keep Maintenance Records

- After a maintenance worker fixes a fault, record the repair in the maintenance log for that equipment.

- These records help with follow-up, troubleshooting future problems, and keeping a clear history of work done on your equipment.