What are Asset Maintenance Records and Why are They Important?

Asset maintenance records are essential wherever you need to either keep track of what has happened with a piece of equipment yourself or document the performance of maintenance, inspections, planned or unplanned checks for audit purposes. It is documentation of maintenance or service interventions performed on a specific instrument, machine, or equipment. Keeping an operation log of maintenance activities is important where legislation or other standards require it, so you can demonstrate compliance. Maintenance and inspection records are also an important part of OHS (Occupational Health and Safety).

What You Can Record in a Maintenance Log

A maintenance log allows you to keep all records of both regular and planned maintenance, as well as repairs or equipment replacements, most commonly these are

- Equipment cleaning

- Calibrations

- Inspections

- Lubrication

- Software updates

- Replacement of a faulty component in the device

- and more

Equipment Maintenance Log

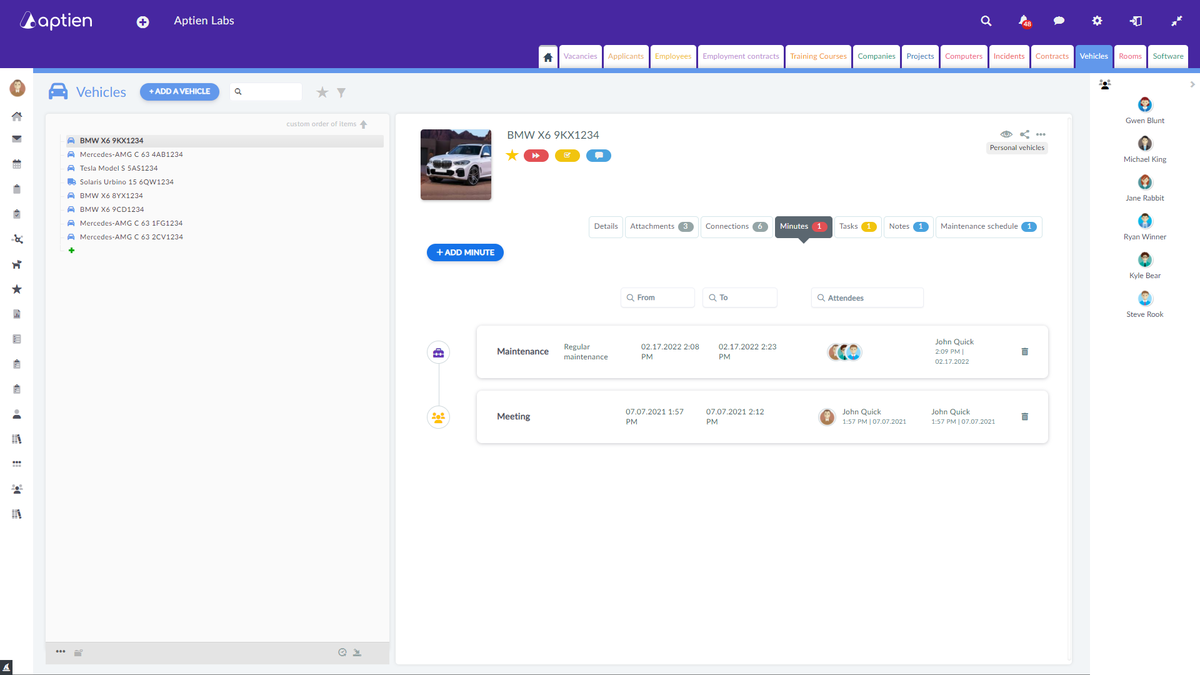

You can keep individual maintenance records as activity logs in the "Entries" tab:

- On the equipment card, select the "Entries" tab.

- Select "+Add Entry" and choose the type "Maintenance".

- A maintenance record will open, automatically populated with your name, and the record will also be automatically linked to the equipment from which you are creating the record.

- In the entry field, record the maintenance activity - what you did.

- In the conclusions field, record the next steps.

- If a follow-up task is needed, create it using the task button.

The created maintenance record is available online using an internet browser. The system provides a full audit trail and restricts access to maintenance records to users with appropriate permissions. Stored maintenance records are indexed and easily searchable.