Durable PPE (Personal Protective Equipment) refers to protective gear designed for repeated use over an extended period. Unlike disposable PPE, which is single-use and needs frequent replacement, durable PPE is intended to be maintained, cleaned, and reused to provide long-term protection in the workplace.

Most Common Durable PPE in Growing Companies

- Hard hats – Protect against head injuries from falling or flying objects.

- Safety goggles and face shields – Protect eyes and face from debris, chemicals, and impact.

- Hearing protection (earmuffs) – Reduces noise exposure in loud environments.

- Respirators with replaceable filters – Provide respiratory protection against dust, fumes, and chemicals.

- Protective gloves (reusable types, e.g., leather, cut-resistant, heat-resistant) – Protect hands from cuts, burns, and chemicals.

- High-visibility vests and clothing – Improves worker visibility in hazardous or low-light areas.

- Steel-toe boots – Protect feet from heavy objects and hazardous surfaces.

What Are Key Characteristics of Durable PPE?

- Designed for multiple uses – Can be worn repeatedly over time.

- Requires maintenance – Needs regular inspection, cleaning, and occasional replacement of parts (e.g., filters in respirators).

- Higher upfront cost but cost-effective over time – Reusability reduces frequent purchasing costs.

- Must meet safety regulations – Should comply with applicable standards (e.g., OSHA and ANSI in the U.S.).

What is Difference of Durable vs. Consumable PPE?

- Durable PPE → Long-term use and requires maintenance (e.g., helmets, goggles, respirators).

- Consumable PPE → Single-use or short-term, disposable (e.g., masks, disposable gloves, shoe covers).

- In PPE inventory management, durable PPE should be tracked for assignment to employees, maintenance schedules, and replacement timelines to ensure ongoing safety compliance.

How to Manage Durable Work Equipment in Aptien

- In the Work Equipment Inventory, select or set up categories for durable work equipment, or create separate Organizers for different types of durable equipment (e.g., laptops, phones, tools).

- Register all durable equipment by adding a new record with detailed information (ID, condition, assigned employee, etc.).

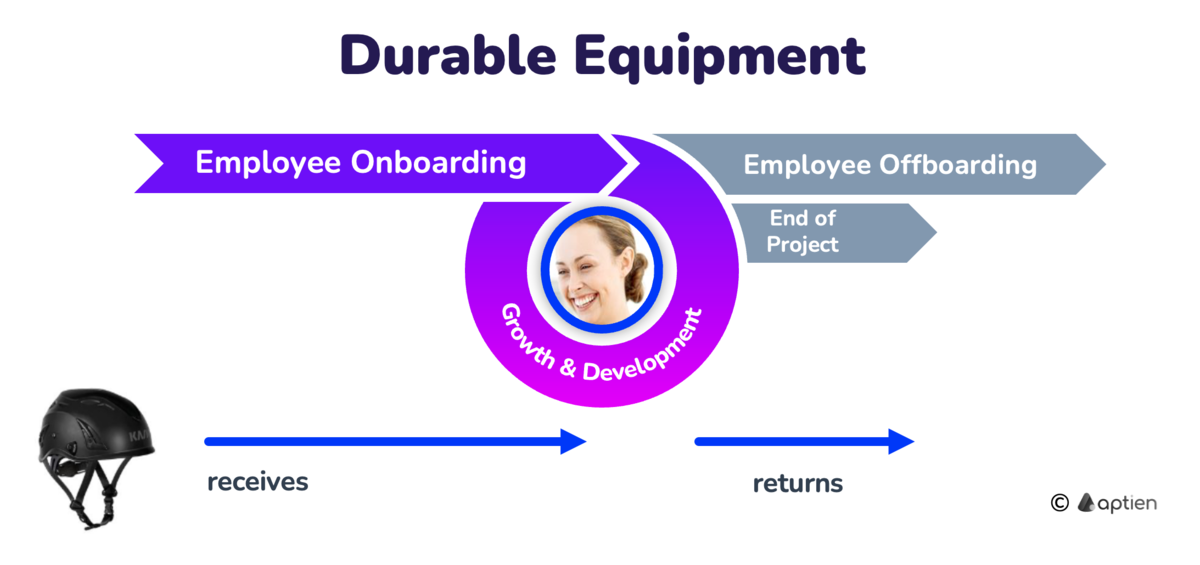

- Issuing Equipment – When equipment is assigned to an employee, Aptien automatically updates the record to include information about the assigned person and issue date.

- Tracking Usage – Regularly monitor the condition and status of equipment to ensure timely maintenance and repairs.

- Setting Up Maintenance Reminders – Create activity plans for regular inspections and repairs (e.g., “Laptop needs a battery replacement”).

- Returning Equipment – When an employee needs to return equipment—either at the end of a project or upon leaving the company—Aptien automatically updates the record to reflect the assigned person and return date.

- Replenishment and Equipment Renewal – Plan and prepare for equipment replacements by setting reminders for upcoming needs based on the lifecycle of each item.