This article is for Maintenance Managers.

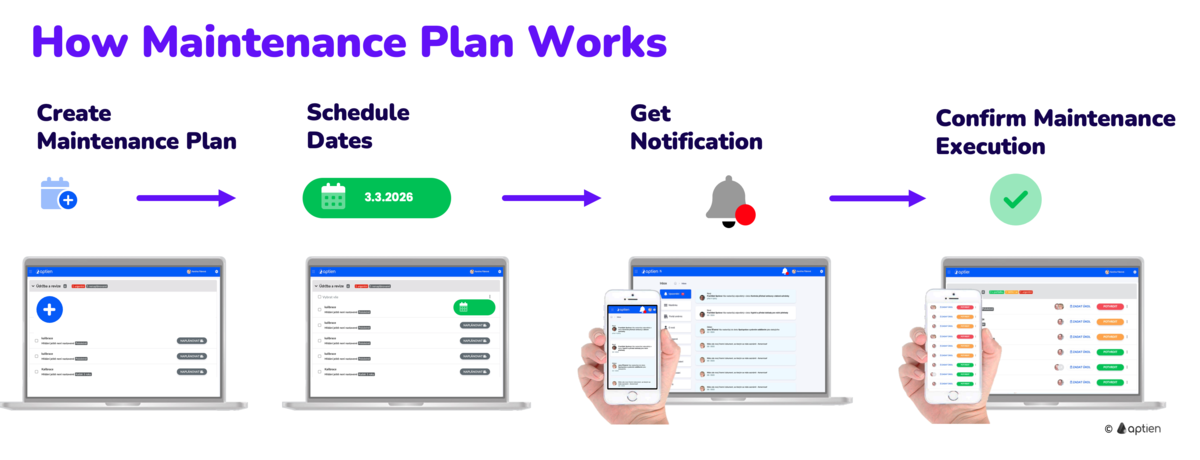

Use maintenance plans to track deadlines and confirm completed maintenance

Maintenance plans are used for planning and confirming the execution of various recurring and one-time maintenance activities, such as regular planned machine maintenance, inspections, checks, or operator training.

- Easily customize maintenance plans to your needs and service intervals for different types of machinery and equipment.

- Schedule individual maintenance activities on specific days

- Receive notifications to perform maintenance on the scheduled date

- Then confirm the maintenance performed

With Maintenance Schedules, you can:

- Create a list of WHAT needs to be done for maintenance.

- Schedule WHEN specific maintenance needs to be done and how often - one-time, recurring, or irregular.

- Assign WHO needs to do it (internal maintenance staff, external service technician, etc.).

- Confirm completion of the planned activity and attach documentation of its completion (e.g., record, photo documentation of the maintenance performed, inspection report, confirmation).

Automated notifications for planned machine and equipment maintenance activities

Maintenance

plans are designed for those who need to schedule maintenance of

machines, equipment, tools and other company assets and want to be

notified in advance of upcoming deadlines. The system not only notifies

you of individual deadlines in a timely manner, but also allows you to

confirm completed maintenance. When confirming individual maintenance

activities, you have the option to attach not only text information, but

also the necessary documentation about the maintenance performed, such as

protocols, photo documentation or other confirmations.

- The system automatically monitors and alerts you to machine maintenance deadlines

- You can see the overall annual plan on each machine

- You confirm the maintenance performed and attach the maintenance reports

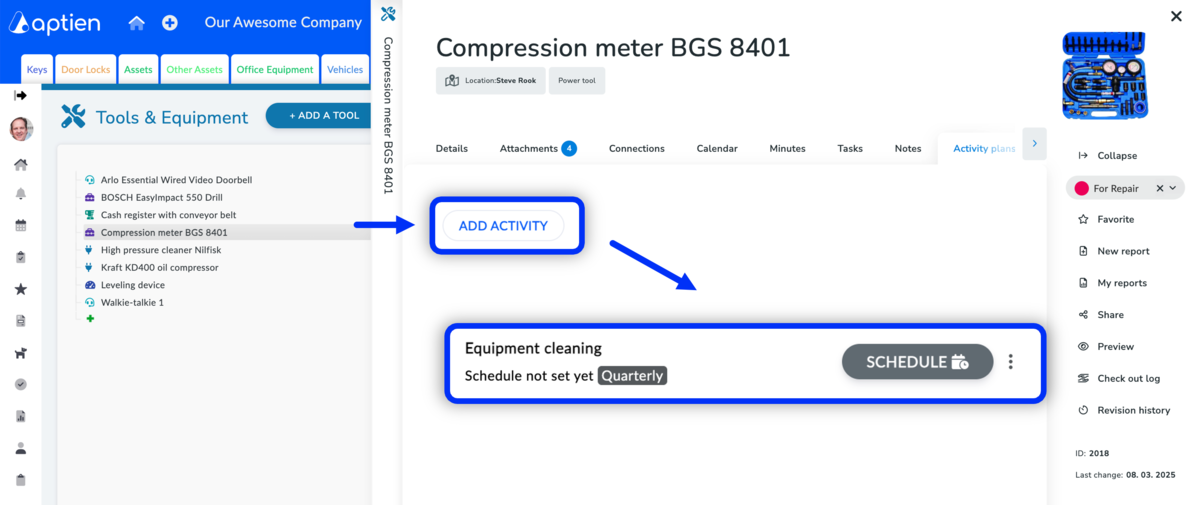

Step 1: Creating a Maintenance Plan

- You create maintenance plans for each type of your equipment, machinery, or devices.

- You can also create an individual maintenance plan for a specific asset.

- You create maintenance plans directly from the asset's card following these steps.

- From there, you can add both individual maintenance plans and plans common to all machines in the given inventory. For example, if you set up a maintenance plan for one elevator, you will have it for all elevators.

- See the guide on how to create a maintenance plan

Step 2. Schedule Specific Maintenance Dates

- Once you have created all your maintenance plans, you need to start the individual schedules, that is, plan or confirm their start date.

- This means setting the first date from which the period should be monitored or when the maintenance activity is scheduled.

- See how to schedule

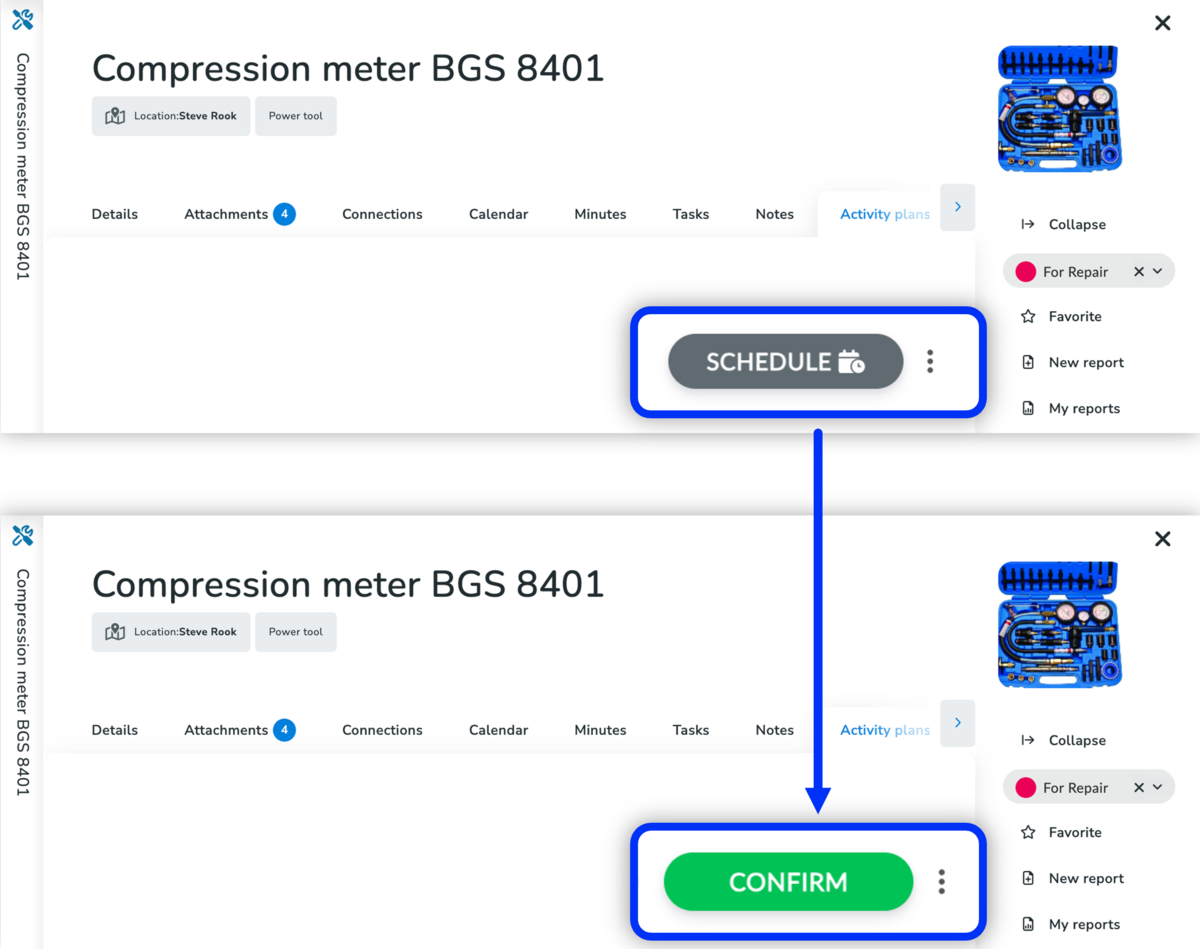

Step 3: Confirmation of Maintenance Completion

- The system automatically sends a notification to the responsible person (facility manager or maintenance worker)

- They confirm the maintenance is completed

- See how to confirm maintenance completion

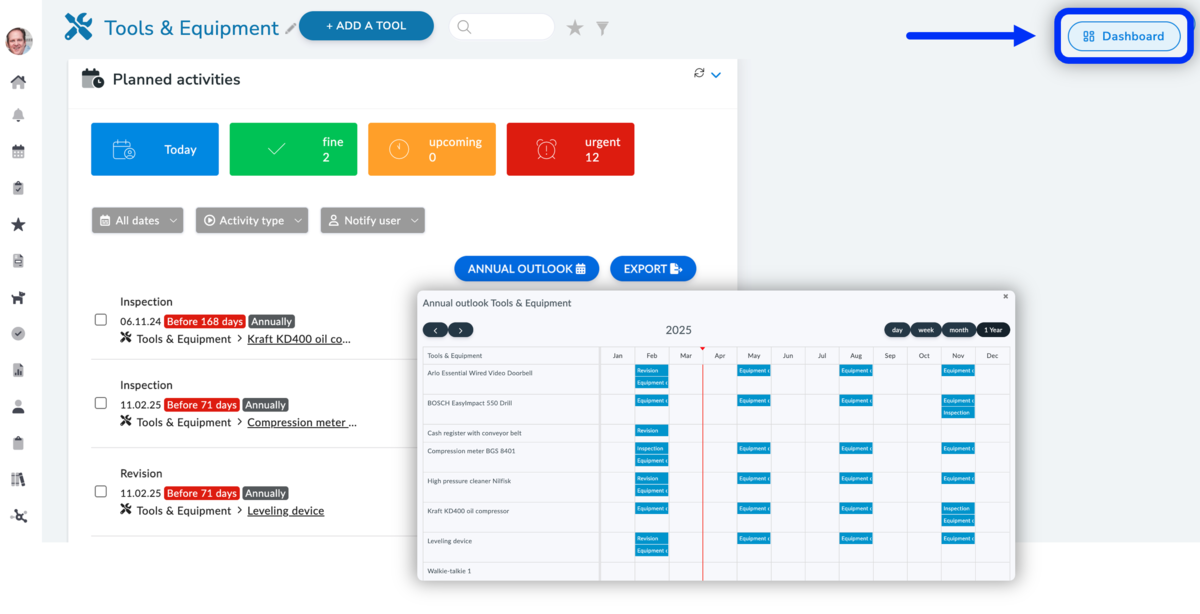

Annual Overview - Maintenance Plan for All Equipment

Get a comprehensive overview of maintenance activities across all your equipment for each month with the annual maintenance plan. You can view this in the equipment register in the "Dashboard" view, the button is located in the upper right corner of the register.

- Click on Dashboard

- On dashboard listing, go to "Activity Plans"

- On the right, you will see the "Annual Maintenance Plan" button

- After clicking on it, you will see the following overview, which displays the next 12 months

Note: If you don't see the Activity Plans report in the Dashboard, you need to customize your dashboard.