Blue-collar workers is a term for workers who perform manual labor. Many blue-collar jobs require training, skills, and a high degree of qualification. You can find many blue-collar jobs that require qualified employees with specialized training. Ensuring workplace safety is also important in most blue-collar jobs.

Qualifications, Training, and Work Equipment for Blue-Collar Professions

- Many blue-collar jobs require highly specialized skills or qualifications

- Blue-collar workers often work with tools, machines, instruments, and equipment that require training

- Qualification and training are also required for health and safety reasons (OHS)

Examples of Blue-Collar Workers in Small and Medium-Sized Businesses

- Manufacturing: Factory worker, crane operator, welding specialist

- Maintenance: Maintenance technician

- Construction: Construction technician, construction equipment operator

- Energy: Technician, electrician

- Electrical installation companies: Service technician, installation technician

- Agriculture: Farm worker, agricultural machinery operator

Effective management of blue-collar workers

Effective management of blue-collar workers in small and medium-sized businesses (SMBs) encompasses several critical areas: tracking qualifications, issuing and managing personal protective equipment (PPE), and providing comprehensive training. Beyond these, fostering a safety-first culture and leveraging modern technologies are essential for ensuring compliance, enhancing productivity, and safeguarding employee well-being.

Tracking Qualifications and Certifications

- Maintaining up-to-date records of employee qualifications is vital.

- This includes documenting certifications, licenses, and training completions.

- Regular audits ensure that employees are qualified for their roles and help identify when renewals or additional training are needed.

Issuing and Managing PPE

- Proper PPE management involves conducting hazard assessments to determine necessary equipment, training employees on correct usage, and maintaining records of issuance and inspections.

- This ensures compliance with safety regulations and protects workers from potential hazards.

Providing Comprehensive Training

- Training programs should be tailored to the specific needs of blue-collar workers, focusing on practical skills and safety protocols.

- Incorporating learning and on-the-job training can enhance retention and applicability.

- Regular refresher courses help keep safety practices current.

Cultivating a Safety-First Culture

- Beyond compliance, fostering a culture that prioritizes safety encourages proactive behavior among employees.

- Recognizing and rewarding safe practices, encouraging open communication about hazards, and involving workers in safety planning contribute to a more engaged and responsible workforce.

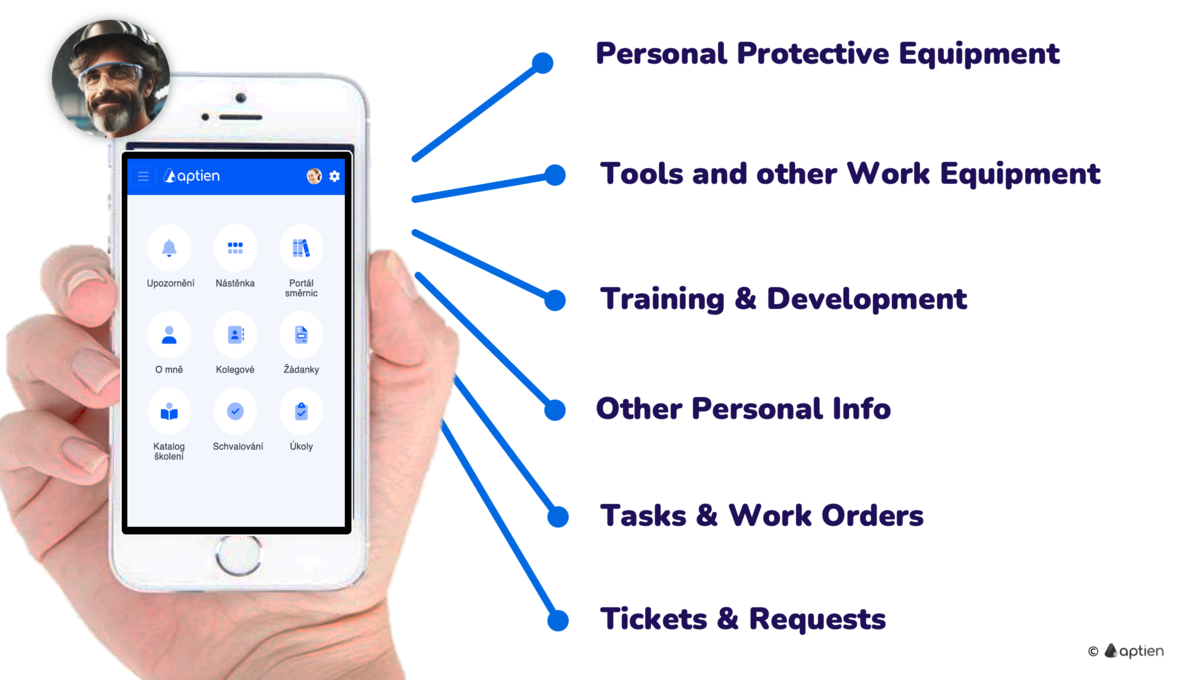

How Aptien Supports Blue-Collar Management

- Tracking Mandatory Training Dates: Ensure all team members complete required training on time, maintaining compliance and enhancing safety.

- Monitoring Work Equipment and issuing PPE: Keep track of maintenance and replacement schedules for work equipment and personal protective equipment (PPE) to ensure everything is in optimal condition.

- Task Management: Efficiently assign, track, and manage tasks to boost productivity and ensure timely completion of projects.

- Team Capacity Overview: Gain a clear view of team availability and workload to optimize resource allocation and prevent overburdening staff.

Industries Employing Blue-Collar Workers

Blue-collar workers are essential in various industries, including:

- Factories and production lines

- Manufacturing and maintenance

- Construction sites

- Power operations and electricity generation

- Mining and food processing

- Oil field work and recycling

- Agriculture and general maintenance