What is availability tracking for?

Availability tracking helps you keep track of how much work equipment you have on hand and how much is currently in use. This means monitoring the number of items issued to employees versus what’s still available in storage. Having this information makes it easier to meet employee needs and plan future purchases.

- Plan Purchases: Helps you schedule buying PPE and other work gear.

- Automatic Updates: The available quantity automatically decreases when equipment is used up, damaged, or expired.

How to Set Up Inventory Counting

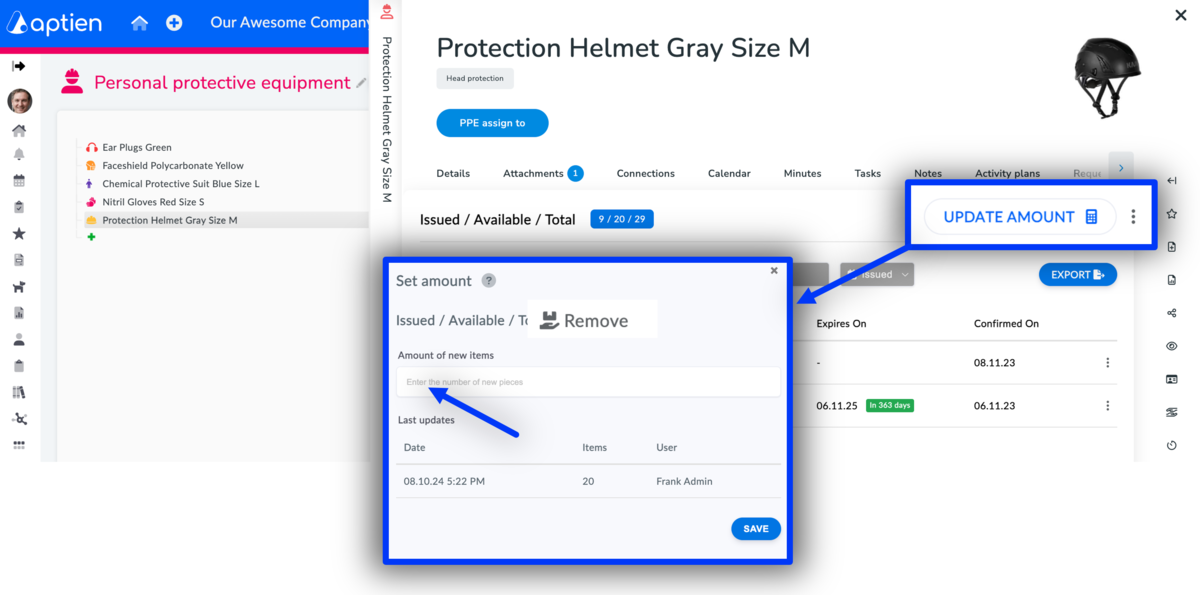

To set up inventory counting for tools or supplies, follow these steps:

- Choose the category where you want to track the item count (e.g., Safety Gear).

- Select the specific item you want to update the quantity for.

- Go to the Assigned tab.

- Click the Set Quantity button.

- Enter the current quantity you have on hand or any new items added.

How to Set Availability for Work Equipment

Planning Replacement and Updating Available Inventory

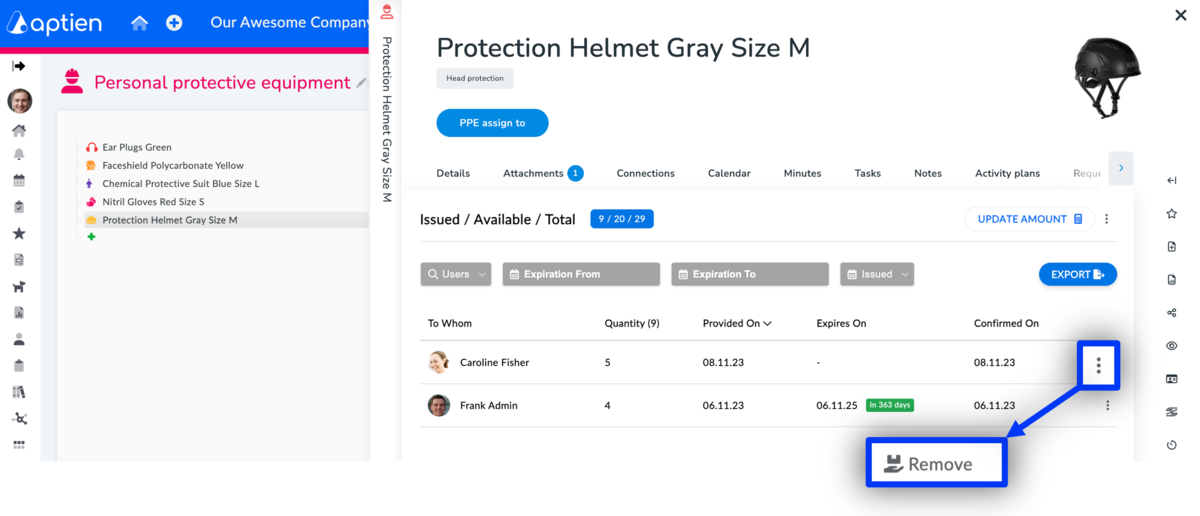

- You can set an expiration date for each piece of work equipment.

- Items with an expiration date will be automatically removed from available inventory on that date, lowering the quantity shown as available.

- Aptien will notify you of these dates on the calendar.

- If items are returned to use (for example, after cleaning, maintenance, or refurbishment), you need to manually update the available quantity to reflect the returned items.

Replacing PPE Due to Damage, Loss, or Updates

- PPE may need to be replaced if it’s damaged, lost, involved in an accident, or if there are new safety requirements.

- Follow these steps when you need to replace PPE under these conditions.