An inspection checklist (also called an inspection sheet) is a organized list of tasks to complete during an inspection. It helps make sure you follow safety rules, industry standards, or maintenance requirements. Using an inspection checklist, small and medium-sized businesses can verify that equipment, processes, procedures, or facilities meet company policies and/or government regulations.

- Inspection checklists are commonly used in facility management, workplace safety, and maintenance.

- They help inspectors perform thorough checks, record results, and spot potential problems before they get worse.

For SMBs, inspection checklists are practical tools for keeping workplaces safe, running smoothly, and staying compliant. They can be used for general safety audits, equipment checks, or compliance reviews to ensure important areas are regularly inspected and properly maintained.

What’s Included in an Inspection Checklist?

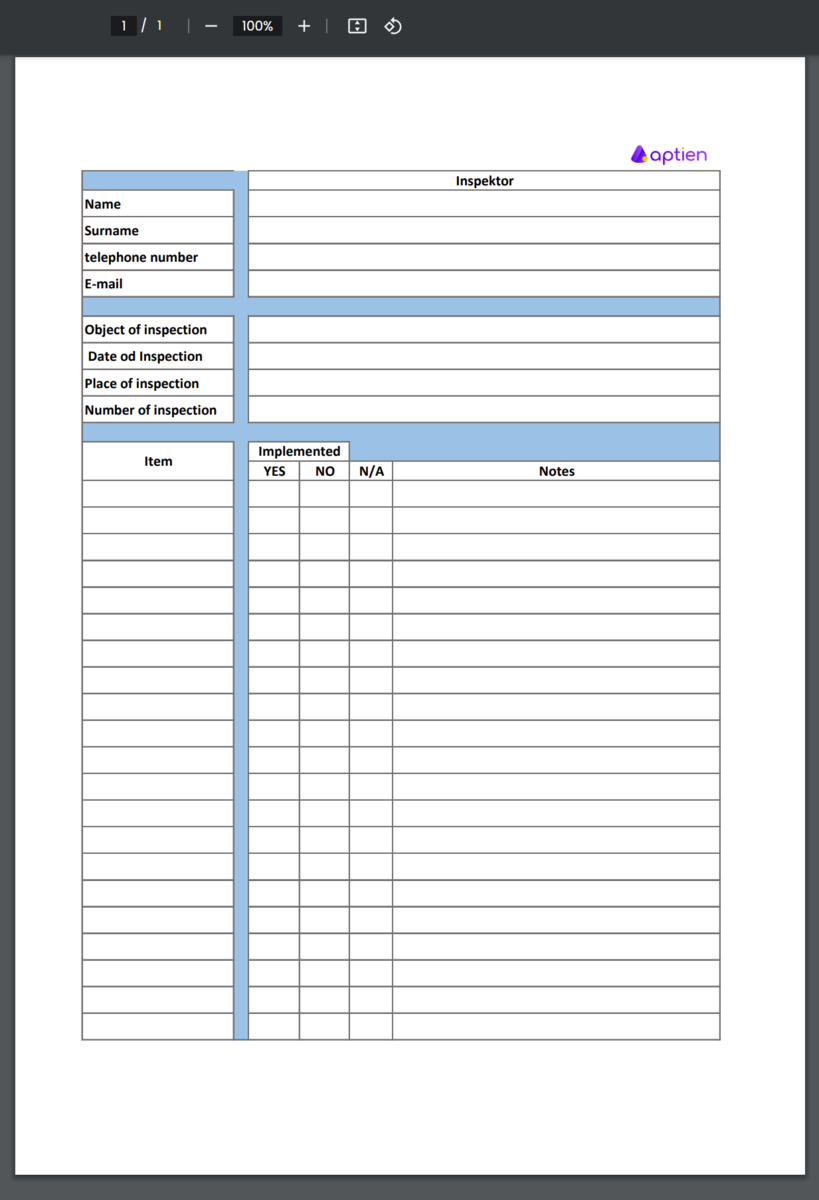

An inspection checklist helps make sure your business meets safety, maintenance, and legal requirements. The items on the checklist will depend on what you’re inspecting—whether it’s equipment, tools, property, or other assets. Since every inspection is different, checklists should be customized to fit the specific item being checked. That said, most inspection checklists generally include:

Basic Information

- Item being inspected (e.g., site, equipment, tool)

- Inspection location

- Date of inspection

- Inspector’s name (and signature)

Instructions for the Inspector

- Inspection details

- Additional notes or comments

Checklist of Hazards, Features, or Compliance Items

- Visual inspection (e.g., visible damage or wear)

- Functional testing (operational checks)

- Safety verification (guards, emergency stops, signage)

- Preventive maintenance tasks (cleaning, lubrication, adjustments)

Each checklist should be tailored to your business’s specific needs, industry standards, and legal requirements. Using a clear and organized checklist helps ensure inspections are complete, properly documented, and in line with safety and maintenance guidelines.

How an Inspection Checklist Works?

- An inspection checklist helps ensure that equipment, assets, or facilities meet safety, maintenance, and compliance standards.

- As each item on the checklist is reviewed and checked off, the inspector confirms that all required components are in proper working order.

- Once the inspection is complete, the item can be approved for use if it meets the necessary standards.

- Beyond compliance, inspection checklists also help businesses maintain safety, quality, and operational efficiency, reducing risks and preventing costly issues.