This article is for those in the company who manage inspections, specifically for asset managers, facility managers or maintenance technicians.

Choose the Best Way to Manage Your Equipment Inspections with Aptien

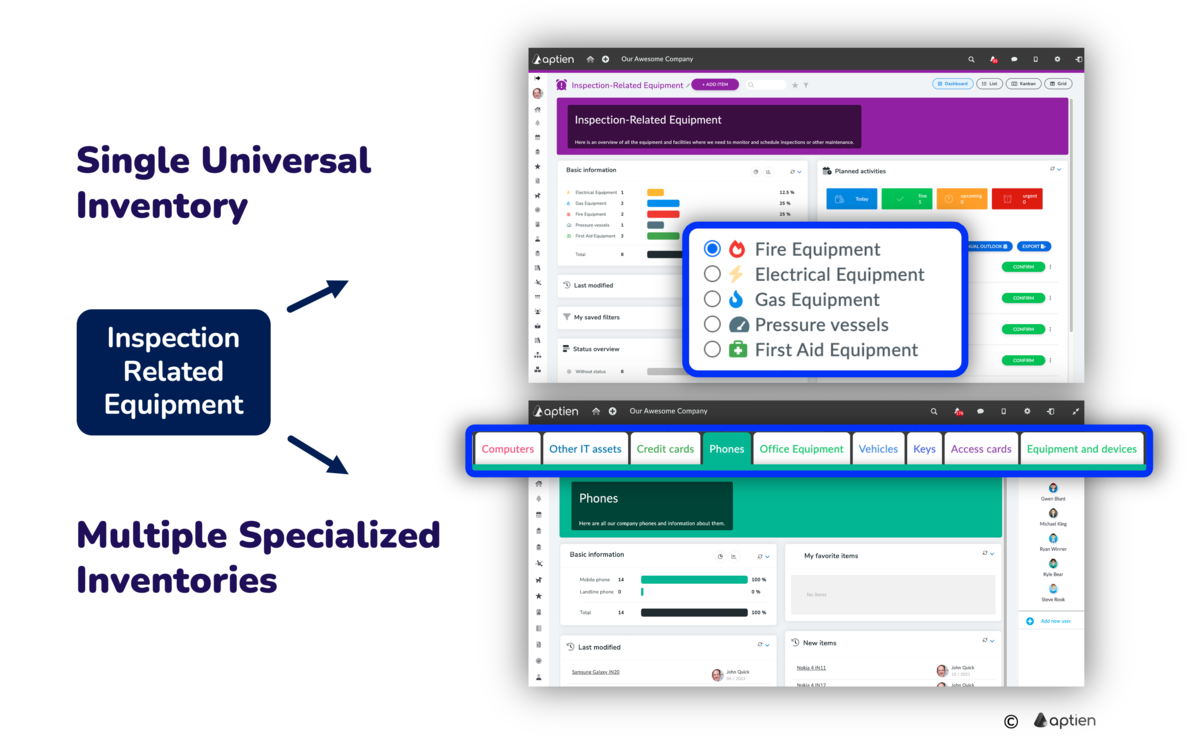

Aptien is not accounting software. Instead, it serves as a robust platform for asset management, helping you track equipment for day-to-day operations, maintenance scheduling, and compliance. You can record assets based on your specific business needs and easily tailor your inspection management processes. Aptien offers two main approaches, with additional customization options available:

- Consolidate all equipment requiring inspection into a single, comprehensive list.

- Categorize equipment into separate inventories (organizers) or groups by type.

1. Single Inventory Approach

- Best for small businesses or teams with limited assets

- Keep all inspection-relevant equipment (e.g., fire extinguishers, HVAC units, ladders, PPE) in one central inventory or organizer.

- Easier to manage in smaller companies where one person is responsible for all inspections.

2. Category-Based Inventories

Best for midsize businesses with more complex needs. Organize inspection items into separate inventories by type:

- Fire Safety Equipment

- HVAC Units

- Vehicles

- Personal Protective Equipment (PPE)

Allows for better delegation and category-specific workflows. Useful when different departments or technicians handle specific areas.